Sustainability

Environment

Sustainability starts with us

Extraction, mining and production

Our slate resources are located in Galicia, Spain. We extract both underground and surface slate there, which we offer under the brand names MONUMENTUM® and InterSIN®.

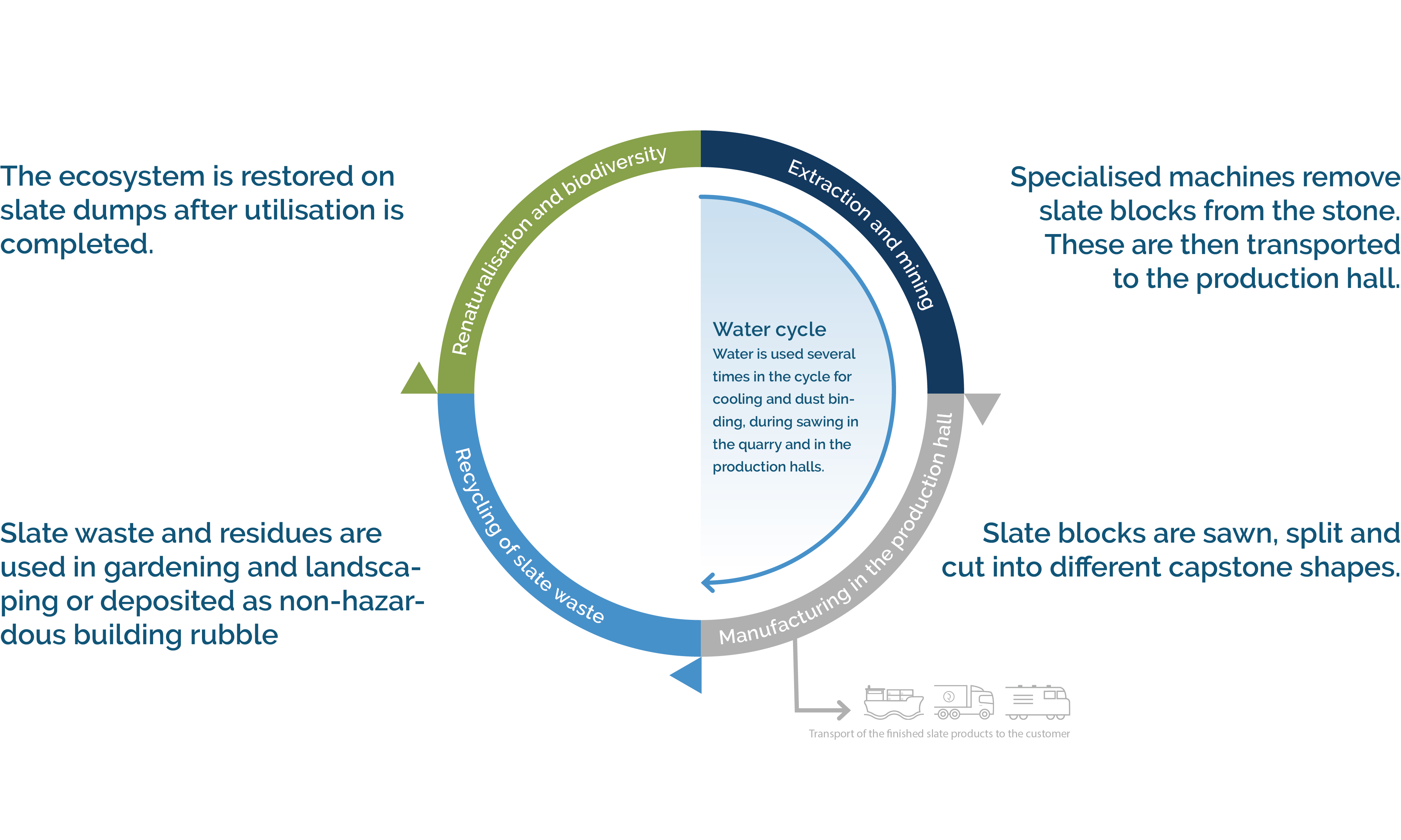

The first step in slate extraction is the development of suitable deposits. This is followed by preparations for extraction. The slate deposits suitable for extraction are made usable by removing the surrounding rock. Shafts and chambers are excavated underground to access the slate deposits. Using wire saws and excavators equipped with hydraulic hammers, blocks weighing several tons are removed from the mountain and transported to nearby production facilities. These blocks are then sawn into more manageable blocks, then split into so-called raw blocks, mostly automatically, and finally trimmed into the final capstone shape using automatic trimming machines or robot technology. The production process is completed by packaging in wooden crates. Careful selection is carried out during all extraction and production steps so that only capstones that meet our strict quality requirements are produced.

Water cycle

Water is mainly used for cooling and dust control during sawing in the quarry and for finishing work in the production halls. The slate blocks must also be kept moist so that they can be split. We take the water required for this from our own extraction, use it several times in the extraction and production process cycle and return it after careful purification.

Slate waste and recycling

The production of slate coping stones for roofs and façades is a domed production process. When producing certain sizes of coping stones, the process inevitably produces other coping stone formats and sizes due to selection and breakage. The raw material is optimally utilized and there is less waste.

Slate that is not further processed after this process can generally be recycled, e.g. in the form of slate chippings, masonry stones and pillars for gardening and landscaping or certain grain sizes as aggregate for various industrial applications.

At the end of their long life cycle, slate products can be disposed of as mineral building material waste without any harmful substances or used for other purposes, e.g. in gardening and landscaping.

Renaturation and biodiversity

Renaturation refers to the process of restoring natural ecological conditions in regions that have been altered by human activity. We restore the areas in which we quarry slate to as natural a state as possible once extraction is complete. To promote biodiversity, we implement protective measures for flora and fauna. For example, slag heaps are filled with soil after use and planted in consultation with nature conservation authorities. In this way, we restore the natural environment and enable a return to the ecosystems.

Scope 1

Direct emissions within our company due to our own combustion of primary energy sources

Fuels

The machines used in extraction and production are currently operated with a seven percent biofuel content in diesel. In order to further reduce our GHG emissions, we are keeping an eye on technological progress and examining the use of alternative fuels (higher biodiesel content or synthetic fuels) or alternative drives with hydrogen or electricity.

Mobility and logistics

The electrification of our mobility sector is a key component of our sustainability plans. Just under 18% of our car fleet in Germany are currently hybrid or electric vehicles. We will continue to increase this proportion. Electric forklift trucks are already predominantly used in production and the central warehouse. We are aiming to switch to 100% electric forklift trucks in the future. We are also planning to electrify passenger transportation to the production halls of our Spanish plants.

Natural electricity

By 2025, we want to cover as much of the electricity requirements at our locations as possible with renewable energies. The Mayen site is already powered by 100% natural electricity, while the proportion at the Spanish sites is around 50%.

PV systems

At the same time, we are working to continuously expand our photovoltaic capacities in order to reduce our Scope 2 emissions. A ground-mounted photovoltaic system went into operation on the company premises in Mayen in 2023. With an area of 1,300 m2 , the electricity yield is around 260,000 kWh per year. The proportion of self-consumption is around 70%. Two photovoltaic systems also went into operation in Spain in 2023.

Energy efficiency

We regularly carry out external energy audits at our Spanish locations in order to reduce energy requirements. Accordingly, ongoing optimizations are made to save energy.

At all locations, the heating systems for the building infrastructure are operated almost exclusively with electricity. The office, training and event building at our headquarters in Mayen was built according to an energy-optimized climate concept and has a geothermal heat pump system.

Scope 2

Indirect emissions from energy purchases from other companies

Scope 3

Otras emisiones indirectas procedentes de actividades anteriores o posteriores

Packaging

The slate end products are packed in wooden crates for safe transportation. The wood for this comes from regional sustainable forestry. In some cases, additional film is pulled over the wooden crates as further protection. These films have a recycled content of around 50%. Overall, packaging accounts for around 1% of our total emissions.

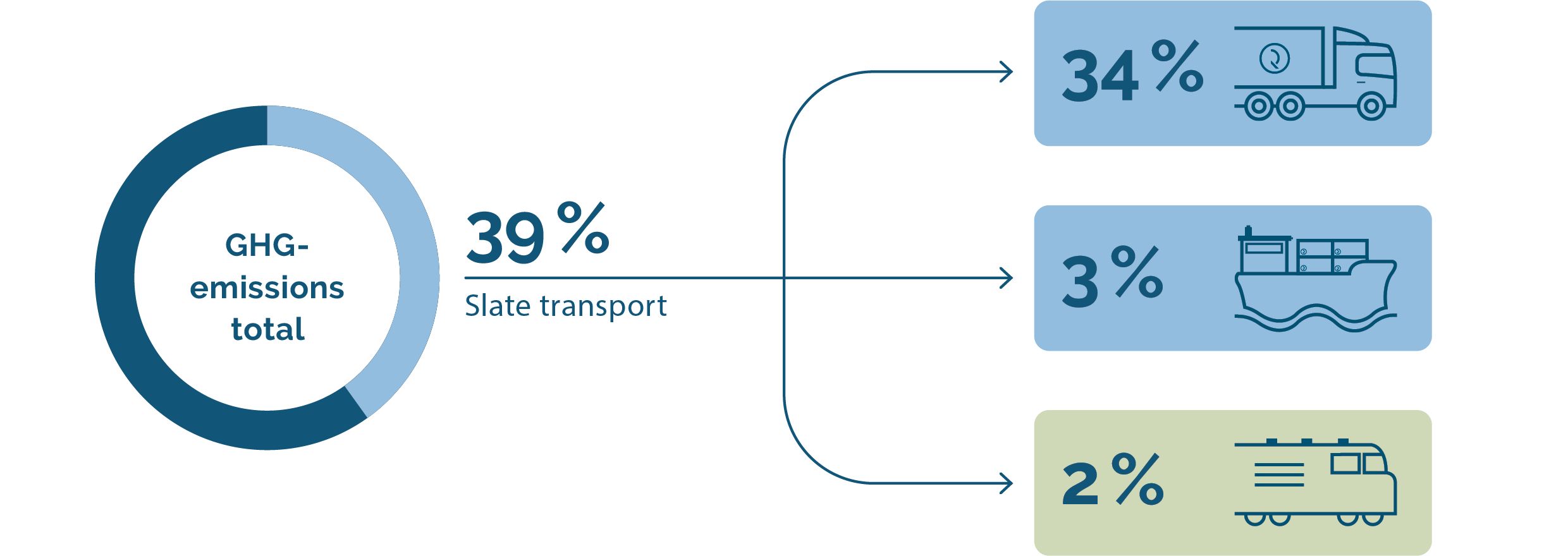

Transportation

Around 39% of our greenhouse gas emissions (Scope 1 to 3) are caused by the transportation of slate to our customers. As the majority of mobility-related greenhouse gas emissions are attributable to truck transport (34 %) - the proportion of ship transport is 3 % - we are monitoring technological developments very closely and examining the use of alternative transport options in order to make transportation even more sustainable. Around a third of the slate we sell in Germany is already transported by rail freight. This has a positive impact on our carbon footprint, as this method of transportation only accounts for 2% of our total greenhouse gas emissions despite the high transport volume. Our ambitions are clear: we want to further increase the proportion of rail transportation and switch to alternative fuels and drives as technological developments progress.

Procurement of slate from third parties

In addition to our own deposits, we source slate from partners. The latter are taken into account in our carbon footprint with the values from the environmental product declaration of the Spanish slate producers' association “Clúster da Pizarra de Galicia”.

Emissions from transportation